LMW ATC CONTRIBUTION TO THE ISROs SUCCESSFUL LVM3 MISSION

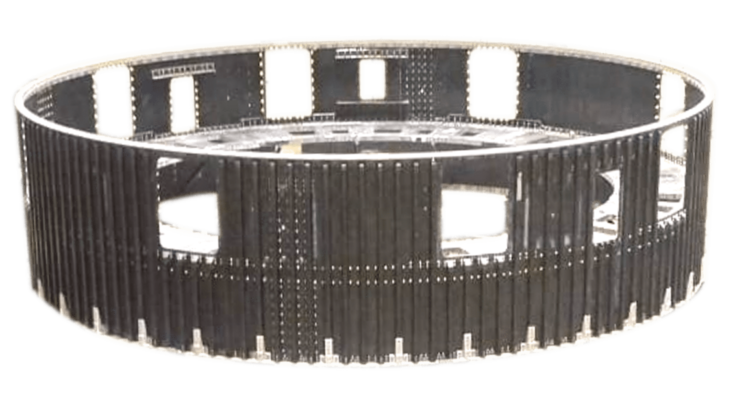

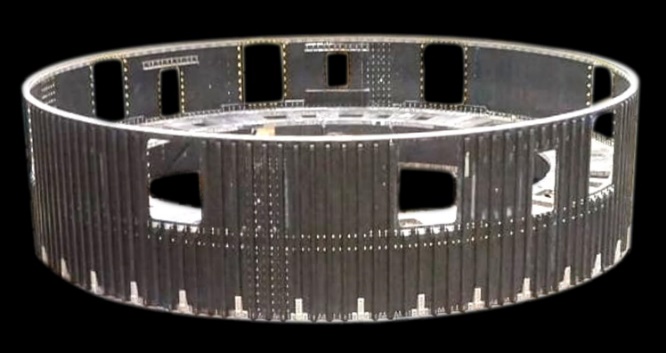

Lakshmi Machine Works – Advanced Technology Centre (ATC) had contributed to ISRO’s successful LVM3 -M3 OneWeb India- 2 mission by producing a flight critical and complex 4m Dia Hat stiffened composite Equipment Bay Shroud that houses sensitive equipment for LVM3, as well as Assembly, Structural Testing, and Non Destr uc tive Testing of 24 Composite tubular members for the Inter Tank Structure that connects the liquid oxygen tank and liquid hydrogen tank of C25 Cryogenic Upper Stage. This Launch Vehicle carries 36 One Web Gen-1 satellit es from the Satish Dhawan Space Centre in Srihari Kota into a circular Low Earth Orbit at 450 km altitude.

4M Dia Equipment Bay Shroud Test Setup for ITSC Tubes

LMW produced 4 Interstage assemblies (S2V, S2S, S3C1 & S3C2) and a sub-assembly called the Piston Cylinder assembly for the separation of the Payload fairing for India Space Research Organization’s (ISRO) successful S SLV-D2 mission earlier this year.

On the occasion of achieving flight heritage for the Composite and Metallic Structures manufactured by LMW- ATC for Launch Vehicles, we wish to emphasize that LMW – Advanced Technology Centre (ATC) is a one-stop sh op for Aerospace & Defence customers. ATC has world-class infrastructure and capabilities, including Quality A ssurance aligning with AS9100 D certification and NADCAP certification for more than 25 special processes, in cluding Composites Process, Chemical Process, NDT, Welding, and Heat treatment. This Composites facility is c urrently being upgraded with cutting-edge equipment, including a C-Scan for quality assurance and a Hot Air O ven for production.